As University of Toronto’s hub for interdisciplinary climate research, Climate Positive Energy (CPE) is pleased to engage experts across all U of T campuses and areas of expertise in addressing the climate challenge and achieving a just and equitable energy transition towards a net-zero future. We are pleased to highlight the work of University of Toronto Scarborough’s (UTSC) Clean Energy Lab.

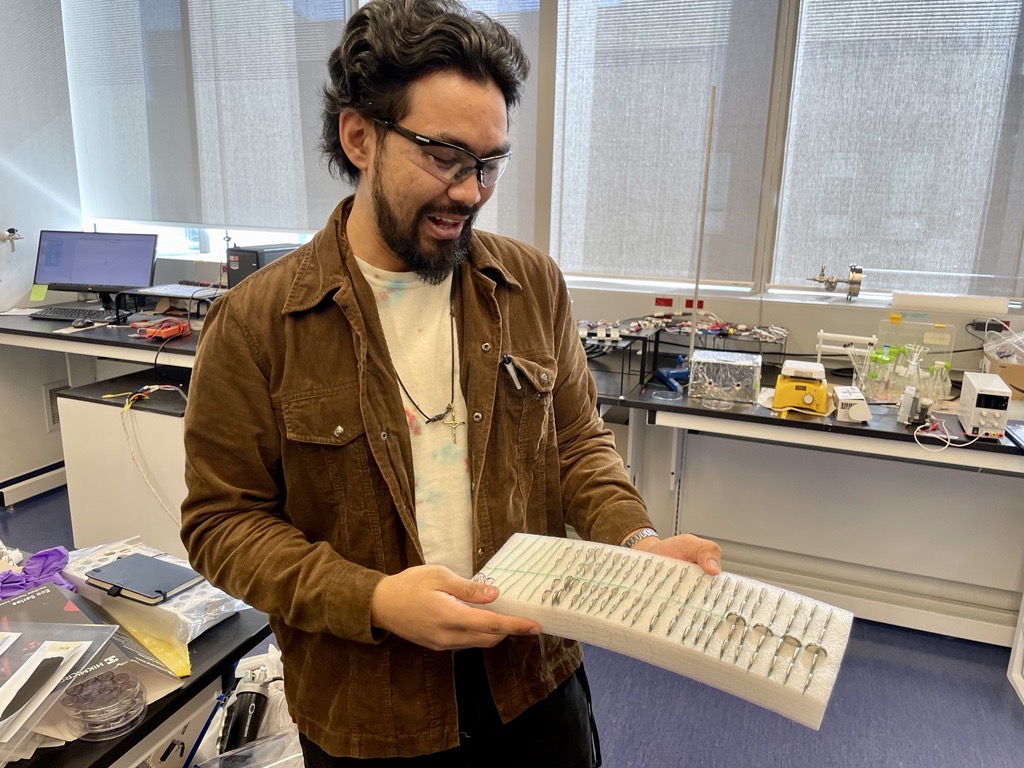

The Clean Energy Lab, led by Professor Alex Voznyy (Department of Environmental and Physical Sciences), unites UTSC researchers in exploring next-generation materials for energy harvesting and storage. The group’s focus is developing new materials for low-cost and scalable energy conversion, storage, and CO2 capture to meet targets for net-zero by 2050. The team consists of more than a dozen researchers, including visiting scholar Ayesha Imtiaz and PhD student Ahmer Imam, who shared insights and updates with CPE during an exclusive lab tour.

The Clean Energy Lab spans spaces across three levels of UTSC’s Environmental Science and Chemistry building. Special lab equipment is used to create and test different battery technology designed by the researchers, from simulations and testing machines to a zero-oxygen chamber, and even a powder x-ray diffractometer that provides details on the battery cell’s structure and other key properties.

Imam speaks to the importance of the equipment in advancing the group’s research efforts: “A lot of the time, the biggest challenge isn’t even the science itself – it’s acquiring and developing the infrastructure for our lab. There are plenty of things we can do with what we have, and many don’t require specialized resources, but a lot of cogs can only start spinning once the necessary infrastructure is in place.”

The Clean Energy Lab’s work on battery research addresses the climate crisis from multiple angles, including both storage and waste. The group recognises the importance of “good batteries” that can store more energy from renewable resources, but also that making these batteries is very costly – “not just in terms of resources, but also environmentally,” says Imam.

One key problem the group is trying to address is stabilizing their batteries, so that they don’t have to produce and then dispose of larger numbers of batteries. “If we can make a single battery last much longer while maintaining a higher energy storage capacity, that’s a big step forward [towards net-zero].”

With cumulative efforts driving the transition to a cleaner, greener future, even small increases in capacity retention per cycle of a battery are incredibly exciting for the researchers. “If a commercial battery loses a certain amount of capacity with every cycle, and the new battery I’m working on loses even slightly less, that’s a big deal for me. It shows that the effort I’m putting into developing that material is making a difference in achieving my goal of more stability and less capacity loss per cycle,” explains Imam.

The team is exploring the role of automation and simulations in their lab. Imtiaz explains that an ideal automation pipeline is through data and software to allow the team to accelerate other hands-on aspects of their research, such as creating solutions to examine properties. “You start with a team analyzing a large dataset of already developed materials. Then, software would extrapolate the ideal properties needed and generate an experimental protocol to synthesize those materials. From there, an automated system, without manual intervention, would use a robot to synthesize different iterations of the material. Any material that doesn’t meet the desired properties would be eliminated, while the best-performing ones would be further refined.” By incorporating AI in the material selection, the process becomes more efficient and less wasteful.

The team is currently collaborating with LG to accelerate their research. Looking ahead, the vision is to see the batteries created in the lab being used in real world applications for renewable energy sources such as solar panels or wind turbines. “The goal is to couple our batteries with renewable energy generators to capture as much energy as possible during peak hours and store it for later use, whether in electric vehicles, household appliances, or other applications,” adds Imam. “We also want to extend the duration of energy storage. If the current maximum storage time is four hours, we want to push it to six hours — or even longer.”

To follow the group as they push the boundaries of next generation batteries for clean energy, visit: http://cleanenergy.utoronto.ca.

Connect with the researchers via LinkedIn:

If you’re interested in partnering with the Clean Energy Lab to accelerate their research, contact info@cpe.utoronto.ca.